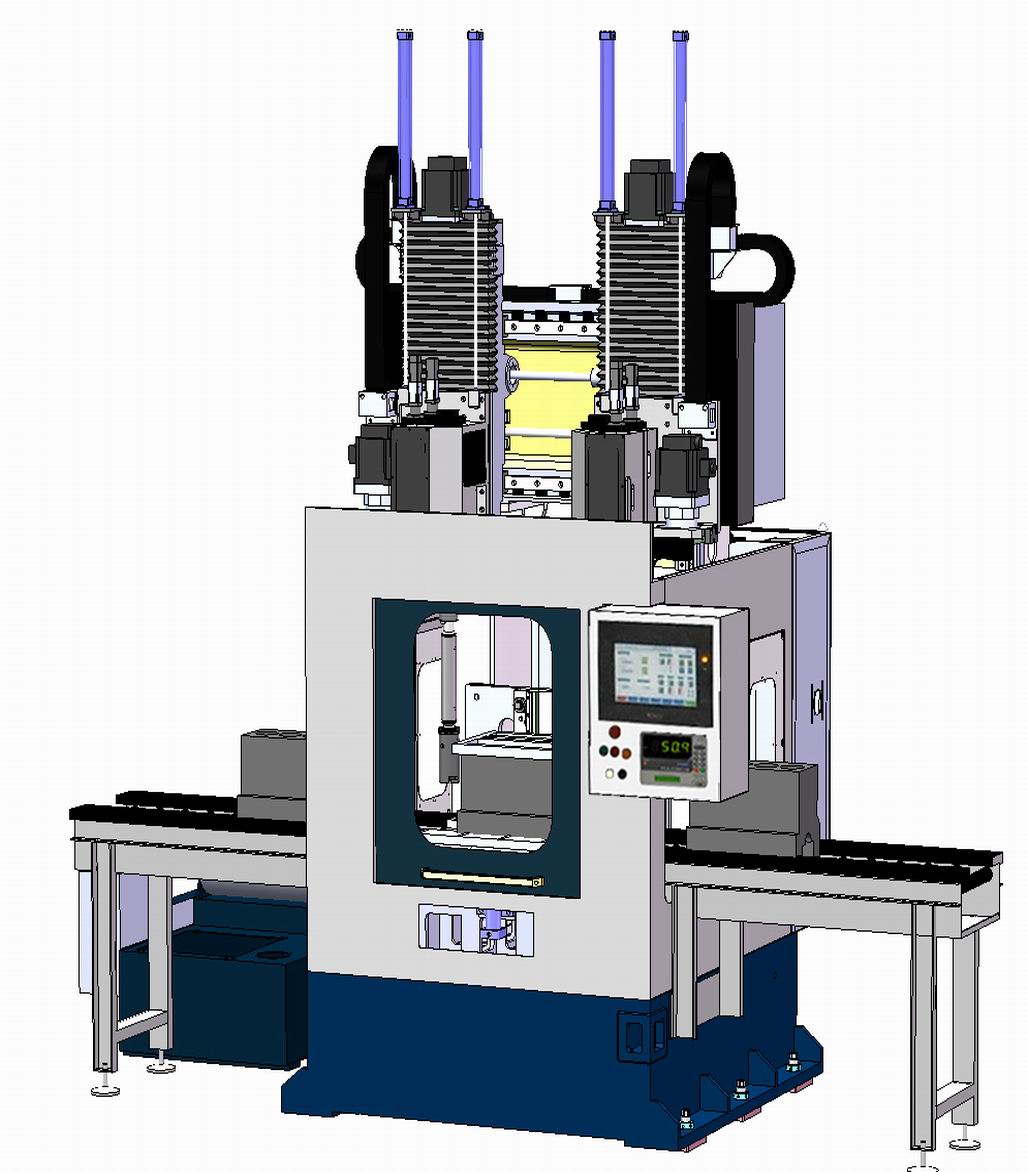

CNC Econimic Honing Machine EDHM16A Series

Practical and efficient honing processing

■ Single-girder gantry frame of machine ensures high rigidity and stability.

■ Machine base using separate water tank design, easy for cleaning up sediment inside water tank.

■ Honing extension system is in hydraulic double-feed design, in which constant pressure control is ensured by use of hydraulic proportion controlling.

■ The machine working table is double rotating table driven driven by hydraulic, single axis, working auxiliary time is zero.

■ Flexible way of fixture types,can design according to customers requirement.

■ The machine is equipped with an on-line measuring system, which ensures the consistency of honing tolerances.

■ The machine is controlled by high-performance programmable logic controller, ensures stable and reliable operation.

■ Integrated platform, with TFT touch panel.

■ Intermittent oil lubrication system, to extend the service life of the sliding components.

| Item | EDHM16A | EDHM16AD | |

| Honing diameter | Φ60mm~Φ160mm | ||

| Max. spindle reciprocating stroke | 600mm | ||

| Max. honing depth | 380mm | ||

| Spindle rotation mode | Inverter motor,with reducer | ||

| Range of spindle speed | 10-300r/min | ||

| Spindle reciprocation mode | Hydraulic proportional servo control, stepless speed regulation | ||

| Spindle reciprocating speed | 2.5-25m/min | ||

| Honing head feed mode | Hydraulic proportional constant pressure double feed | ||

| Max. stroke of coarse feed thrust bar | 30mm | ||

| Table dirve mode | Hydraulic rotary table | Hydraulic rotary table

/Hydraulic movable table |

|

| Number of stations in table | 2 | 2/4 | |

| Table indexing time | 4.5s | ||

| Positioning accuracy of table | ±4“ | ||

| Dimension of table | Φ650mm | 300X400mm | |

| honing accuracy | Cylindricity:≤0.01mm ,Roughness:Ra0.2 μm | ||

| CNC system | OMRON PLC | ||

| Hydraulic unit | double variable pump, oil cooler | ||

| Cooling unit | Separate tank, magnetic drum 2-stage paper filter, constant temperature cooling system , with oil cooler | ||

| Lubrication unit | Centralized ration auto lubrication | ||

| Pneumatic unit | Standard pneumatic control system with air filtration devices | ||

| Measuring system | On-line measuring from CHINA | ||

| Honing head and connection rod | Double-feed honing head, controllable extension/retraction pressure of honing sticks in different stages | ||

| Honing chucking | Down press type oil cylinder, Optional rubber sleeve hold fixture | ||

| Chucking clamping mode | Face down press,Optional pneumatic rubber clamping | ||

| Machine guard | Semi-closed guard | ||

| Work lamp | Energy saving lamp | ||

| Machine noise | <75db | ||

| Machine color | Base: dark grey; other: white | ||

| Total power of machine | 30KVA | ||

| Net weight of machine | Approx 5000KG | ||

| Overall dimensions (L×W×H) | 4064×2824×5304 mm | ||

Product Class

- CNC Boring Machine

- CNC Honing Machine

- Grinding Machine

- Honing Accessories

- Honing Machine Remanufacturing

- Lathe Machine for Cylinder liner

- Production Line solution

Contact Us

Name: Jason

Whatsapp: +86 13338867379

Tel: 86-514-85106981

E-mail: careway@china.com

jason@china-honing.com

Add: No.69 Jinye Road, High-Tech Zone, Xi'an, China.

Contact us On Line.